Sounds too good to be true. There must be a catch. There is always a catch.

Using molten salt as both the heat transfer fluid and the thermal storage medium sounds great. Problem is, this is somewhat innovative, and the demo plant has only been in operation since 2004. So while six years of performance history is good, it is not the same as the 20+ year track record that trough using thermal oil can point to in the Mojave Desert. So it doesn't have a 20-year track record. Who cares? Well, the investment banks care, and since they hold the purse strings on the funds to build utility-scale solar plants, if they ain't happy, ain't nobody happy.

As analyzed in the recently released GTM Research CSP 2011 report, the LCOE for CSP and PV are currently pretty close (around $0.12-$0.15/kWh in the U.S. Southwest). The problem is that PV costs are expected to decline faster than parabolic trough costs over the next decade (see chart below).

_521_322_80.jpg)

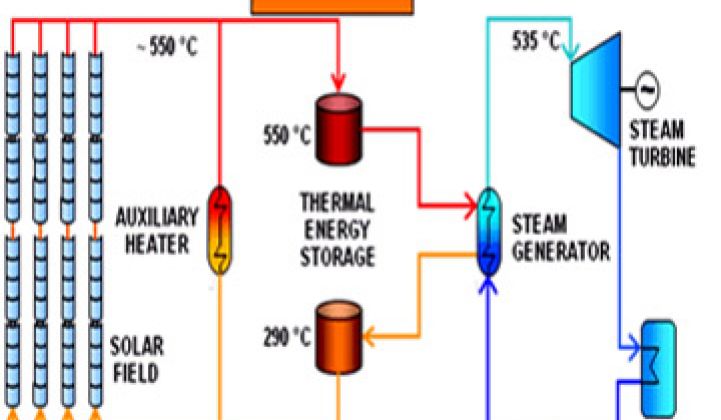

Perhaps utilities will be willing to pay extra for storage. Or perhaps innovators will find a way to reduce trough's costs to keep pace with PV. But how? Archimede believes the answer lies in the use of molten salt as the heat transfer fluid, which would allow plants to operate at higher temperatures -- generating more electricity and reducing the costs of storage (as smaller tanks could be used). While attending the World Future Energy Summit in Abu Dhabi, I was able to meet with Paolo Martini from Archimede and he shared some specifics on the benefits of using molten salt.

Benefits include:

1) Lower plant cost

The plant cost should be 20% lower than a traditional trough plant (thanks to the removal of heat exchangers and the use of smaller storage tanks).

2) Higher electricity output

The higher temperatures will allow plant efficiency to be 6% better than traditional trough plants (thanks to the removal of losses from the heat exchangers, and from matching the preferred temperature of turbines).

3) Lower O&M expense

Maintenance expenses are lower as there is no need to replace the oil and reduced receiver tube replacement requirements (when using oil, the tubes may need to be replaced due to vacuum corruption).

4) Easier to site

Another strength of using molten salt instead of thermal oil is that in Italy (and France), the government only allows trough plants with oil in industrial zones, whereas plants with molten salt have more flexibility in choosing a location.

The net result of all these benefits is a potential significant reduction of LCOE.

One concern for the technology is that molten salt has a freezing point of 230 degrees Celsius, so the system needs to be carefully designed to prevent the salt from solidifying. As a precaution, the Archimede systems incorporate electric heater elements as a backup in case of malfunction. But according to Archimede, since the demo plant began operation in 2004, the auxiliary electric heater has never been needed.

Archimede is moving forward with its technology in Italy and India. The company now has a 100 MW authorization in Italy: 25 MW near Rome, 65 MW Sicily (likely two plants), and 10 MW in Puglia. These plants would be eligible for a €0.28 feed-in tariff, as long as they are completed by 2013. The plan is for them to break ground by end of 2011.

In addition, Archimede has a DOE/NREL project using an innovative molten salt composed of three compounds, which lowers the freezing point to 120 degrees Celsius (vs. 230 degrees Celsius), with the expectation of significant reductions in thermal losses.

Will using molten salt as the heat transfer fluid be the silver bullet that significantly lowers the cost of CSP? Archimede is betting that it is.