When it comes to resiliency, utilities are taking many different paths. Some are raising substations to protect them from flooding. Others are replacing wood utility poles with metal ones, and others still are investing in state-of-the-art software and hardware that allows the grid to automatically isolate faults.

The U.S. Department of Homeland Security, however, has other ideas about what a resilient grid might look like. As part of its aptly named Resilient Electric Grid, or REG, project, DHS is giving $60 million to AMSC (NSDQ: AMSC) and Commonwealth Edison to install a high-temperature superconductor cable to increase the resilience of ComEd’s system in Chicago.

The project will be both the first commercial application of a superconductor cable for resiliency in the U.S., and, at more than 3 miles long, the largest project of this type in the world. The cables will connect critical substations in the Chicago’s downtown business district.

“We view this project as a natural extension of the infrastructure improvements and technological upgrades that have been underway for the past two years as we develop and deploy the smart grid,” Anne Pramaggiore, president and CEO of ComEd, said in a statement.

So far, DHS has only put in $1.5 million for the first phase, which involves taking a draft scope of the work and turning it into a detailed implementation plan over the next six to nine months. Years before Sandy, DHS began looking at the reliability of urban grids in the wake of the September 11 attacks and the 2003 blackout, and the agency has plans to install up to three pilot projects.

“We’re trying to bring inherent reliability to the whole system,” said Daniel McGahn, president and CEO of AMSC. “The magic happens in the wire.”

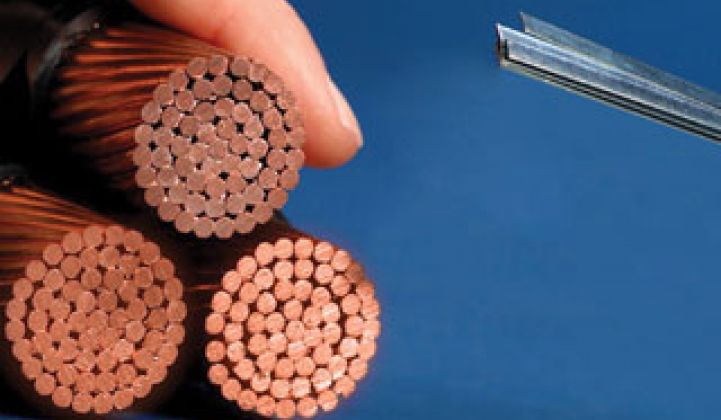

Instead of building in redundancy, such as additional substations, the superconductor cable will provide enhanced capacity and reliability. The high-energy-density wire, which can carry about ten times the power of traditional cable, can automatically contain faults within the wire. The cables conduct electricity with near zero resistance at -320°F, compared to -460°F for traditional superconductor cables.

Superconductor cable projects have popped up worldwide in the past five years or so, but so far, they have yet to take off for grid applications. LS Cable and AMSC are working together in South Korea with KEPCO on a HVDC superconductor cable. In Germany, Nexans is replacing a high-voltage cable with a superconductor cable less than a mile long.

“Utilities around the world are investing tens of billions of dollars on smart grid technology designed in part to create a more redundant and resilient grid,” said McGahn. “We believe that the Resilient Electric Grid system, which is enabled by AMSC’s unique high-temperature superconductor technology, has the potential to play a significant role in protecting the infrastructure assets so vital to our electrical systems.”

McGahn describes the wires as a sandwich with a series of ceramics between an outer metal packaging. If a fault occurs as the power runs through the superconductor, the electrical path is moved to the outer metal, which acts as a resistor and quenches the fault before returning it to the system. “It’s a much more elegant solution” compared to other hardware and software solutions for fault protection, said McGahn. “But our competition isn’t FLISR or copper cables,” he added. “It’s [the prospect of] building another substation.”

Besides fault restoration, the wires can also carry more capacity than traditional wires so they could be used to deal with capacity constraints in certain parts of the grid if one substation does not have enough power to supply the neighborhoods it serves. As with energy-efficiency measures to defer substation upgrades, the appeal of superconductor cables is their ability to more fully leverage the capacity already on the grid.

The full project is expected to take about 3 1/2 years in Chicago, according to AMSC, although the company expects future deployments to move more quickly.