Water, microorganisms, soil and a ball that could pass like a cat toy: Together, they can cut the cost of air purification, says Bio-Reaction Industries.

The Tualatin, Oregon-based company has devised a novel system for filtering and cleaning the air in paint shops and other industrial workplaces that effectively relies on the ability of microbes to eat carbon-based molecules. Air containing volatile organic compounds (VOCs) gets passed through two different microbial reaction chambers and the end result is water vapor, heat, and carbon dioxide. (Pictured above: One of the company's "cat toys of the apocalypse," as far as VOCs are concerned. Microbes contained in the soil will break apart VOCs and thereby filter the air.)

Although carbon dioxide is often produced in the process, the technique far more environmentally friendly and cheaper than the conventional technique for getting rid of VOCs, said Karl Mundorff, Bio-Reaction's CEO. Typically, paint shops eliminate VOCs by incinerating them in furnaces fueled by natural gas, which generates in NOx gases and far more carbon dioxide. Carbon taxes tip the balance further in favor of bio-oxidation. The technique can also be used to eliminate the overpowering smells emanating from industrial plants.

"We have 75 to 95 percent of the destructive effect but we save on natural gas," he said. "We lower the operating cost by 90 percent with the same capital cost."

Last year, Bio-Reaction installed nine systems in North America (bringing the country's total to 25 units) and two in China. Toyota and Louisiana Pacific are customers: The Louisiana Pacific system filters 160,000 cubic feet of air per minute. The company's systems start at around $1 million, cost on average around $2.5 million and can run as high as $10 million to $15 million, depending on the air flow requirements. The end result looks like a chemical processing plant. The Environmental Protection Agency has certified the plants in the U.S.

Bio-Reaction's process marks yet another milestone in growth of industrial microbiology. Yeast and other microorganisms have for centuries been used to produce cheese, wine and beer and in the 20th Century been exploited to produce antibiotics.

But In the last several years, a number of startups have proposed harnessing the metabolic process of natural, genetically enhanced and genetically manipulated to produce fuel (Amyris, Zeachem), fertilizer (AgraQuest), industrial chemicals (Genomatica), semiconductor insulators (Cambrios) recyclable plastid (Bioplastech) and other materials. Scientists at Georgia Tech are also studying to see how microbes can be used to detect leaks at nuclear repositories and MIT has made battery components.

Microbes, after all, are essentially little chemical factories that require less external energy than industrial boilers to perform reactions. They also don't need health and benefits packages, can endure difficult enviroments and be sacrificed by the thousands on a daily basis. Someday, they could be recognized as the employees of the century.

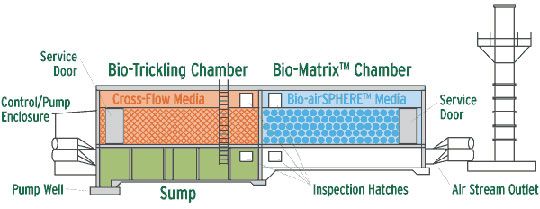

The process works as follows. Air containing substances such as formaldehyde, benzene and/or methanol is captured, mixed with water vapor and channeled into what the company calls a bio-trickling chamber. This first chamber is filled with plastic strips coated in water infused with bacteria.

A diagram of how the process takes place. Water-soluble materials are eliminated in the first phase. In the second, soil microbes captured in balls gobble up non-suluble materials.

Water soluble compounds will have already been dissolved into the humidified air. When these droplets come into contact with the moist strips, the bacteria come into contact with the compounds and oxidize the harmful substances.

"The microbe reaches through the water/water interface," Mundorff said. The company, in fact, started off trying to tackle the problem of storm water contamination.

Substances that aren't water soluble are metabolized by the wiffleball of destruction (otherwise known as the BioSphere Media) in the next chamber. The spheres – which measure about 1.3 inches in diameter – are packed with soil infested with microbes.

The microbes employed by Bio-Reaction are somewhat common varieties. Genetic modification is not necessary.

"There is a microbe for any carbon molecule," Mundorff said. "They can eat alcohols at a 90 percent level in 6 to 12 seconds."