Vijit Sabnis, VP of Technology and a co-founder of triple-junction solar cell manufacturer Solar Junction spoke on Wednesday night at the monthly IEEE PV gathering at PARC in Palo Alto, California. CEO Jim Weldon, along with Jeff Allen, VP of Business Development at Solar Junction, lurked in the audience.

Sabnis gave a hopeful update on the compound semiconductor startup which aims to provide higher efficiency solar cells for the still-nascent concentrated photovoltaic (CPV) market. I say "still nascent" because despite the decades of development and hundreds of millions invested, terrestrial CPV has deployed only a few tens of megawatts in the field. Compare that to the almost routine commissioning of 50-megawatt crystalline silicon-based solar power plants.

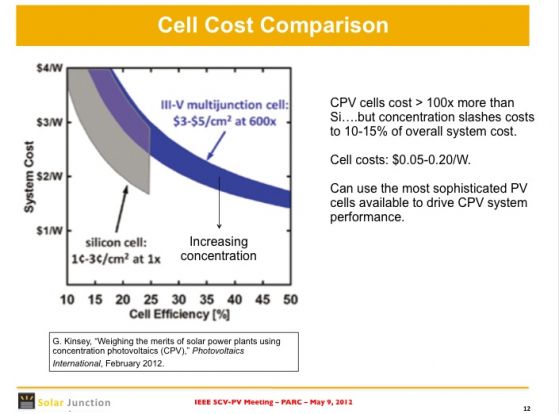

Sabnis finds a positive in that. He asserts that no other photovoltaic technology has the headroom to improve its efficiency like triple-junction solar cells. He also asserts that because T-J cells are a smaller proportion of the system bill of materials, no other cell technology's improvement can leverage down the cost of the system like CPV.

The largest CPV deployment in North America is the 5-megawatt Hatch site in New Mexico. That site should yield its title soon to the 30-megawatt Alamosa site in Colorado, both with hardware from Amonix. SolFocus has a project in development in Mexico that could eclipse the Colorado CPV farm. Soitec has large CPV plants in the works as well including over 150 megawatts of PPAs with San Diego Gas & Electric and a 50 megawatt plant in South Africa.

Vital stats on Solar Junction:

- Founded in 2007

- Headquartered in San Jose, California with 44 employees

- Pilot production line is approximately 5 megawatts of 500X annual capacity on 4-inch wafers

- The firm has raised more than $50M in equity from VC firms ATV, DFJ, NEA and strategic investor and epi-manufacturing partner IQE

- Financial support from US DOE and NREL -- $3 million PV Technology Incubator and $21.5 million Sunpath PV Manufacturing Initiative

- Currently holds triple-junction cell efficiency world record of 43.5 percent

- Transitioning from R&D to high-volume manufacturing on six-inch wafers starting late this year

Sabnis cited research that showed CPV to have the potential to achieve the lowest cost of electricity in hot, sunny, high-DNI regions with single-axis c-Si as CPV's largest competitor. Although only about 85 percent of sunlight is typically collected in high concentration systems, CPV might achieve these potential low costs with the levers of improved concentration, increased volumes, and improvements in efficiency. That's the hope, anyway.

While Greentech Media has observed Demi Moore's law in c-Si progress, Sabnis asserts that M-J solar cells are more able to harness a Moore's law cost and performance progress. He likens the multi-junction solar cell to an LED in reverse and said, "We look, feel, and smell like an LED company." He notes that Solar Junction can get two kilowatts from one 4 inch wafer under concentration at 1000 suns and could produce 200 megawatts of power from its relatively small factory floor if fully populated with equipment.

It's obvious that Sabnis is passionate about this technology saying, "This technology really excites me" and cites "the awesome performance of these solar cells." He called out the performance of M-J cells at high temperatures due to the high-voltage output of 3.5 volts (headed to 4.5 volts) compared to silicon and that CPV loses 4 percent of its output in high temperature compared to 15 to 20 percent for c-Si. Sabnis also notes that industry concentration figures have increased from 500X to 1000X and beyond.

For Sabnis, "The most exciting thing is what the future holds and the headroom." He cited several studies showing 70 percent theoretical efficiencies from a 5- or 6-junction cell. More practically he sees 50 percent cell efficiency achievable in three to five years which could get DC module efficiencies to over 40 percent.

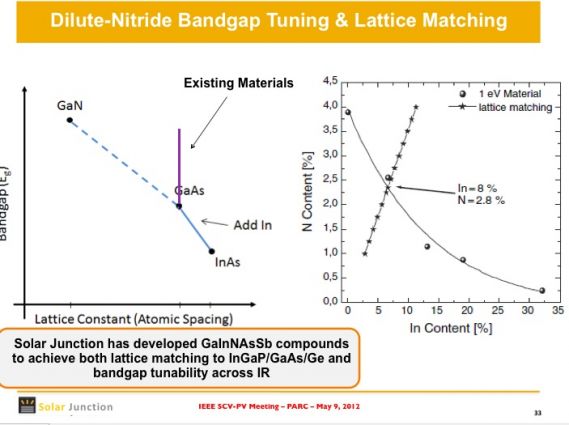

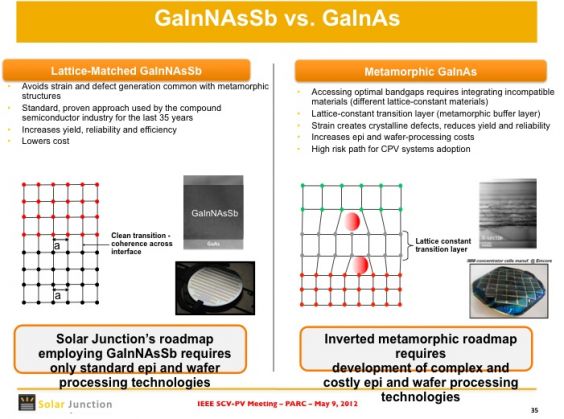

The secret sauce in the Solar Junction recipe is the firm's dilute nitride technology. According to Sabnis, "If you add little bit of nitrogen, you can reduce the bandgap and lattice constant of that material." He also notes that the addition of indium provides a tunable bandgap infrared material with "a fully lattice-matched platform." Lattice mismatch can cause microcracks or dislocations that serve as minority carrier recombination sites.

Sabnis said that the competition had given up on dilute nitrides but Solar Junction went from ten percent to 43.5 percent efficiency in two years as measured at NREL and Fraunhofer ISE on cells from off the production line. Quantum confinement structures, such as quantum dots or wells, can manage lattice mismatch but efficiency will top out at about 42 percent with that technology, said Sabnis.

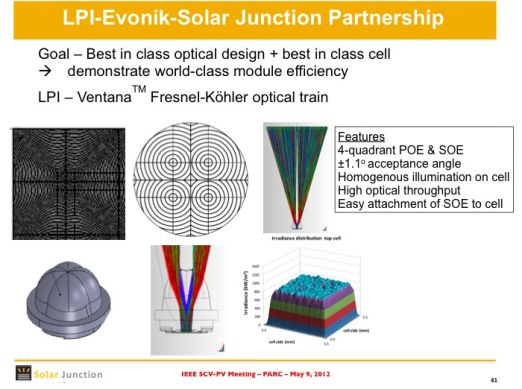

The company is collaborating with LPI to develop a demonstration vehicle, utilizing best-in-class cells and packaging, of a unique 4-element fresnel lens that could reduce overall tracker costs, while providing very high module efficiencies.

So -- great technological progress at the CPV cell level is being made by Solar Junction (and competitors Semprius, JDSU, Encore, and Spectrolab), but system vendors have to cut cost at the systems level in order to compete with the plummeting cost of single-axis c-SI.