REhnu (pronounced “renew”) is a relatively new name in the concentrated photovoltaic (CPV) world. They're early stage and have a slightly different twist on the architecture of a CPV system.

But let's start with the name. The 'RE' in REhnu stands for Renewable Energy. The "hnu" is from the formula E=hν or E=hnu, which relates the energy ('E') of a photon to the photon’s frequency, given by the Greek letter ν, or “nu,” and Planck’s constant 'h.'

Which, in case you haven't been keeping track, places us deep in central Nerdistan.

Dr. Roger Angel, the designer of the CPV product and, presumably, the company's name, has a background in astronomy at the University of Arizona. Angel leads the UA solar high concentration photovoltaics research group and has co-authored three patents covering the technology licensed by REhnu. His technological innovations are used to make the world’s largest and most aspheric telescope mirrors.

Building the world's biggest telescopes has, in Angel's view, given him the ability to think through the CPV design as a system. It's allowed Angel to approach the problem without any previously held conceptions about CPV -- and not to feel compelled to make CPV look like flat-panel PV.

Angel is looking to drive costs down to a dollar per watt installed by scrubbing cost out of a few areas -- primarily by using the least amount of glass and steel possible.

REhnu's design uses what Angel calls "the native form of manufactured glass" -- the 3-meter sizes from a glass factory -- as the reflectors. The design allows a window-glass factory to be modified to produce the glass reflectors, which are then arranged on a steel space frame. The space frame has rigid nodes and the "mechanics of the 2-axis tracker respects the nodes," according to Angel.

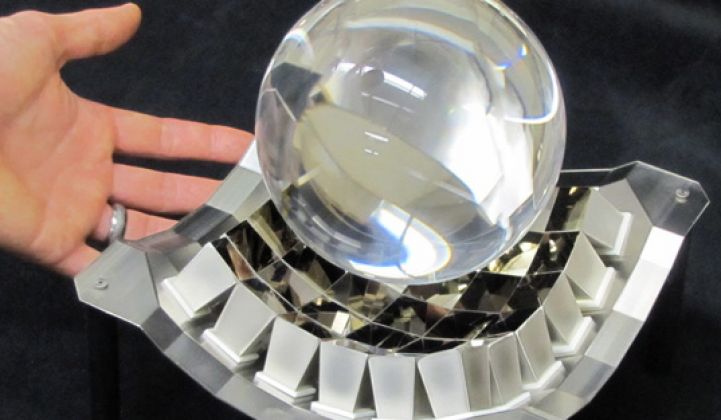

The system operates at 1000X concentration, and with a cost of $5.00 per square centimeter for the triple-junction solar cells, Angel says that gets the cell cost down to 15 cents per watt. The system doesn't place a lens on every solar cell, as is the case in almost every CPV architecture. A ball lens at the focus of each large dish sends the same amount of light power to each of 36 cells, so that all of them produce the same amount of electrical current. Active cooling is used rather than massive aluminum heat sinks to scrub off heat.

![]()

Prototype of REhnu's 20-kilowatt CPV system

Angel estimates the mass of steel as 100 kilograms per kilowatt of output and expects to have one complete 2+kilowatt dish/receiver working by the end of May and eight of them in a full 20-kilowatt system early next year.

Land usage is estimated at 4 acres per megawatt, while the ground-clearance and open design of the space frame are designed to be gentle to the environment at the installation site.

UA has raised $4 million in R&D funding, mostly from the DOE and Science Foundation Arizona. REhnu has raised about $1 million. This year, the firm will raise another $1 million, and once the full tracker unit is populated and generating 20 kilowatts, Angel looks to raise a $25 million Round A to build manufacturing facilities and get to two megawatts of production.

CPV is on a bit of a roll lately. Amonix has PPAs signed with Southern California Edison for a total of 28.5 megawatts, Soitec has a 150-megawatt project brewing (contingent on DOE loans), and there are going to be some more CPV announcements coming this way soon.

CPV vendors remain in a cost race with the crystalline silicon solar behemoths while holding a potential advantage in high-temperature environments and in land usage. Perhaps a telescope scientist can crack this nut.

3.1 meter-square reflector prototype made from a single sheet of glass at the University of Arizona

UA President Robert Shelton, U.S. Representative Gabrielle Giffords, and REhnu CEO Roger Angel examine the first prototype 3-meter segmented primary reflector.