The last 16 Academy Award winners in the Visual Effects category use Autodesk design tools, acccording to the company.

Autodesk describes its multiple visualizing tools as “digital prototyping software.” The software allows users to create three-dimensional virtual realities in which to challenge and perfect their designs.

“It lets people design, visualize and simulate their ideas,” explained Autodesk Cleantech Partners Program Manager Susan Gladwin, “whether that’s designing for buildings, infrastructure, or -- in the case of manufacturing -- most anything that can be made.”

The digital prototyping, Gladwin said, “lets you explore your ideas thoroughly, simulate them under different conditions and try out performance optimizations.” Designers, she added, “create with pixels before they create with atoms,” and, in the process, “play with their ideas before they make them real.”

Beyond the doors of creativity this opens, Gladwin said, “it saves a huge amount of cost.”

Following the marketplace success of its seven suites of software tools (building design, entertainment creation, factory design, general design, infrastructure design, plant design and product design), Autodesk formed its Cleantech Partners Program in July 2009 to select worthy innovators to support.

The company decided it did not want to wait until the innovators with those great ideas could afford the software. “The idea was, ‘Let’s get them the software now -- let’s not wait,’ because great ideas can get stopped by the lack of resources,” Gladwin said.

The program makes Autodesk's software available to aspiring companies with big ideas that need testing but have little resources for it. “They get up to $150,000 worth of software for $50.”

Autodesk has worked with companies developing ideas in solar, wind, ocean energies, biotech, and greentech buildings and transport around the world, including the U.S., Canada, Europe, Israel, Japan, and Singapore.

By supporting such companies, Autodesk is helping hundreds of small innovators across what business calls “the valley of death” between concept and commercialization. Though this likely creates for Autodesk a client for life, it also facilitates broader social benefit. “We are definitely making an investment in this field, in order to accelerate innovation and get it to market faster,” Gladwin explained, but it is also “our contribution.”

Gladwin described some examples of what greentech companies were able to do with Autodesk design products.

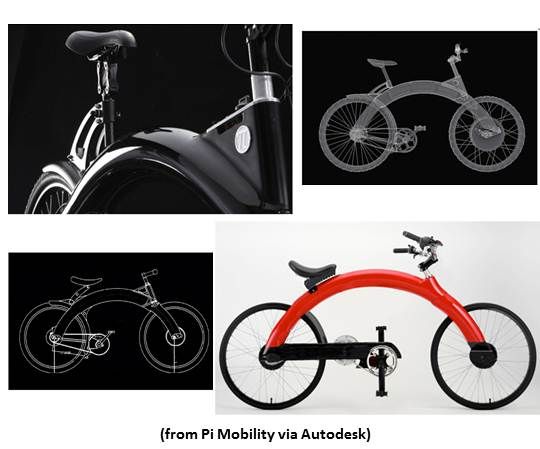

General Compression, a company doing compressed air energy storage for wind, modeled improved storage; Tesla Motors perfected its Model S body design; Poduvhat, a tidal energy company in Serbia, tested its concept against the harsh ocean environment; Utility Scale Solar created a better heliostat; Pi Mobility made a more cost-effective electric bicycle; and Marine Innovations & Technology turned a concept for an offshore oil drilling platform into a floating wind turbine.

Electric bike maker Pi Mobility’s design team, Gladwin said, had spent only three weeks trying out virtual design variations of its arched aluminum tube frame with Autodesk Inventor when it realized that increasing the diameter of the arched tube by a half an inch would save $335,000 per year, suggesting a potential savings of millions over time.

Marine Innovations & Technology (MI & T) is on that journey across the Valley of Death thanks to Autodesk, engineer and co-founder Dominique Roddier told GTM.

Roddier and partner Christian Ceomelli, both Parisians with PhDs from UC Berkeley, worked together in the offshore oil industry in the early 2000s, perfecting smaller drilling platform designs. Both became interested in offshore wind because, as Roddier put it, “That’s where the future is.”

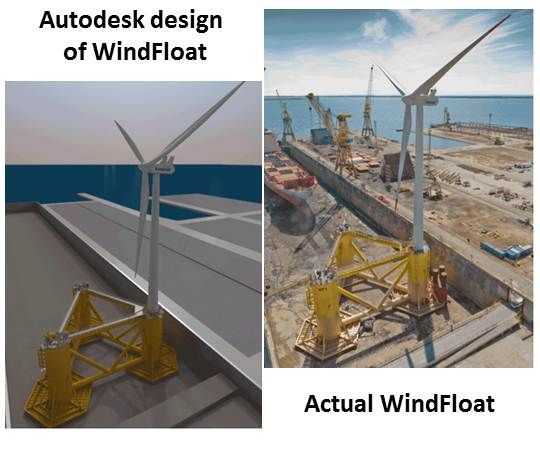

By 2009, they had gone independent and were working with Principle Power to turn their small offshore oil platform into WindFloat to harvest deep ocean winds.

WindFloat’s deceptively simple, semi-submersed stability comes from three submerged ballast columns attached by a triangle of beams. It is passive equilibrium, because the turbine tower sits atop a column that contains relatively little water ballast, while the other two columns have enough ballast to steady the approximately 400- to 800-ton turbine. Broad flat heave plates at the bottom of each ballast column add stability.

The WindFloat prototype, carrying a Vestas two-megawatt turbine, initiated testing last November in the Atlantic Ocean off the coast of Portugal.

WindFloat’s final design emerged from some 600 to 700 drawings reviewed by multiple engineers in multiple locations. It was a consultation, Roddier said, that would have been impossible without the Autodesk software the Cleantech Partners Program provided. The software was even more crucial as the prototype went from design to fabrication, Roddier added.

One employee’s sole job was to build “a very big, very detailed 3D model” from the drawings, using Autodesk software. In the process, he repeatedly caught small, often simple, design flaws, any one of which could have cost too much time and money.

“We went from start of engineering to end of fabrication in 18 months,” Roddier said. “It would not have been possible with other tools.”

Seemingly even more impossible is that, thanks in part to the power of virtual design, the 15 people of MI & T and Principle Power are in a tight competition with HyWind, a floating wind concept created by massive and immensely wealthy Norwegian national oil company StatOil, for dominance in floating deep water wind.