QTEROS (formerly SunEthanol) is a cellulosic ethanol company developing a conversion technology based upon the "Q microbe." The company was founded by two researchers at the University of Massachusetts and has raised more than $29M from Battery Ventures, Soros Fund Management, Venrock, BP, and Valero.

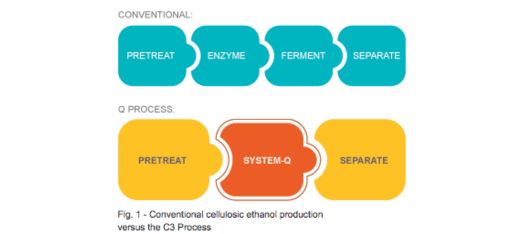

The Q microbe was discovered near the Quabbin Reservoir in rural Massachusetts. In conventional cellulosic ethanol processes, biomass is first broken down into simple sugars and then fermented into ethanol. With a little help from genetic modification, the Q microbe naturally produces enzymes that can both break down the biomass into sugar and ferment it into ethanol. This technology is called consolidated bio-processing technology (also known as "C3" or "Complete Cellulosic Conversion") and could reduce the costs of producing cellulosic ethanol by up to 30%, as the need for other, more costly enzymes is avoided. Additionally, the company intends to utilize excess lignin for power generation, further reducing energy costs and GHG emissions.

Recently, the company unexpectedly replaced long-time CEO William Frey with former Verenium executive John McCarthy, whom we interviewed.

GTM: What do you intend to do differently than your predecessor?

JM: I have two broad objectives. First, to substantially accelerate the key technical and engineering initiatives of the R&D group. The second is to establish strategic partnerships with companies that can substantially accelerate our commercial development. Similar to how I brought BP on board at Verenium, I am seeking to do a similar thing with QTEROS.

GTM: What is the company's commercialization strategy

JM: We have never intended to be a build-own-operate (b-o-o) company. We have always been a technology provider. The amount of capital required to b-o-o is significant. We are building a pretreatment facility in Western Mass, but it is not a fully integrated pilot plant. We intend to partner with other companies with pilot plants, which could include partial ownership in the project.

GTM: What do you think are the biggest obstacles inhibiting industry commercialization?

JM: Capital has been scarce. The changes in the USDA and DOE due to the new administration has slowed the application process. That being said, the last couple of years are a lot more exciting than the previous 6-7 years. The industry is a lot smarter now with larger players. It's a good thing that companies like Abengoa, DuPont, BP, etc are involved.

GTM: What feedstocks are you targeting and how did you choose those?

JM: The good news about our organism is that it is feedstock agnostic. That said, my own personal belief is that the greatest possibility is for grasses and canes. Cellulosic ethanol companies that will do the best will be the ones that are located in temperate regions in southwest and southeast.

GTM: What makes your process unique compared to other cellulosic producers?

JM: Our organism produces enzymes necessary to break down the biomass into sugars and then ferment. It produces enzymes and consumes the sugar into ethanol. The acid in the mild acid hydrolysis releases the C5 hemicellulose sugars. The cellulose comes out of the pre-treatment. Our organism breaks the cellulose into the c6 sugars without needing to add enzymes. The organism then consumes the sugars and then excretes ethanol.

GTM: Ethanol is much maligned due to energy density issues and infrastructure incompatibilities. Is the company looking at applications other than ethanol?

JM: The Q microbe produces enzymes, which is unusual, and allows us to break down sugars inexpensively. If you can produce cheap sugars, then the ability to genetically modify the organisms to do all kinds of things. The organism is modifiable and applications are potentially broader than ethanol. We are beginning to look at it.