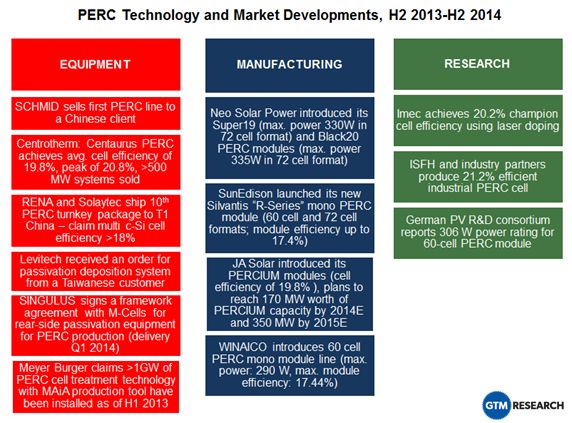

Over the course of the last year, progress in the manufacturing of passivated emitter rear contact (PERC) solar cells has begun to reveal the full technological and commercial potential of this new cell architecture. There have been developments in equipment and manufacturing processes, as well as research, summarized in the following graphic.

Source: GTM Research PV Pulse

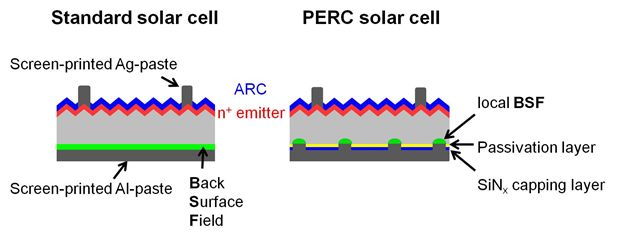

PERC technology increases conversion efficiency by adding a dielectric passivation layer at the rear side of the cell (shown as the yellow layer in the image below). Higher efficiency levels in standard cell architectures are limited by the tendency for photogenerated electrons to recombine. PERC cells maximize the electrical gradient across the p-n junction, which allows for a steadier flow of electrons, reduction in electron recombination, and higher efficiency levels.

Source: ISFH

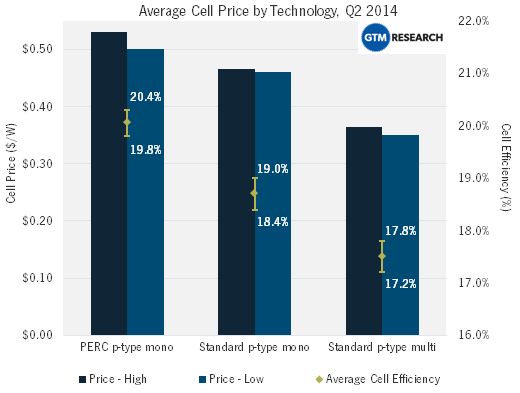

The increased demand for PERC is being spurred by its potential to provide better efficiency at a competitive cost. As noted in the graph below, p-type mono PERC cell efficiency claims in the lab range from 19.8 percent to 20.4 percent, while standard p-type multi production line efficiency is in the range of 17.2 percent to 17.8 percent. The upper-edge range for mass produced PERC cells will depend on line execution as PERC capacity ramps up. Despite that caveat, reported PERC commercial module efficiency claims still trump multi-module levels; current values are 17 percent and 15 percent, respectively.

Source: GTM Research's Global PV Price Outlook, Q3 2014

These higher efficiency claims have piqued the interest of the downstream market, especially in Japan and the EU, with high-efficiency-focused suppliers ramping up capacity. A majority of capacity additions are taking place in Taiwan (Neo Solar, WINAICO, Gintech), though there have been recent commercial manufacturing announcements from JA Solar and SunEdison, as well.

Due to its high price and optimized efficiency, a majority of near-term demand will likely continue to be in residential, high-ASP markets. JA Solar is launching its PERC product, PERCIUM, in the Japanese, British, Israeli, Chinese, and German markets.

Moving forward, the key challenge for this cell technology will be reducing production costs. Currently, p-type mono PERC cells are on average 1.5 times the price of standard p-type multi cells. The price differential reflects the advanced cell architecture's higher cost. This premium is on par with that of standard mono cells, which are priced ~1.3 times as much as multi cells. However, PERC cells currently provide a higher level of efficiency gain, with PERC cell efficiency that is 15 percent higher than standard multi cells and 7 percent higher than standard mono cells. This indicates that with incremental improvements in cost structure and efficiency, PERC mono will be well on its way to being competitive with standard mono technology.

***

Jade Jones is an upstream analyst at GTM Research and the author of the recently published report, Global PV Pricing Outlook: Q3 2014. For monthly upstream data and analysis, see GTM Research’s PV Pulse.