OK, name three types of electrochemical cells.

- Batteries, of course.

- Fuel cells, because reasons

- And third (drumroll, please) is the thermally regenerative concentration cell.

It's that third, more obscure species that startup NanoConversion Technologies is betting will make residential combined heat and power cheaper and more efficient.

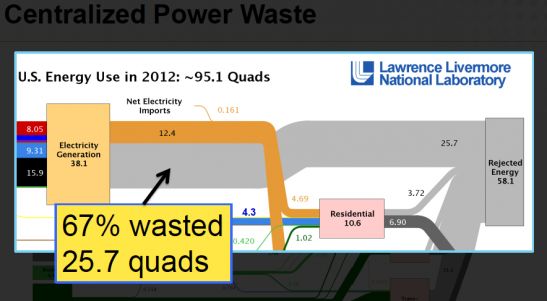

The U.S. is increasingly burning cheap natural gas -- but centralized power generation, transmission and distribution is wasteful. The CEO of NanoConversion Technologies, Mike Staskus, said that the conversion efficiency of a gas-fired power plant to a residential wall plug is about 33 percent, citing Lawrence Livermore National Laboratory's "spaghetti chart."

Staskus suggests that making electricity from gas, close to the user, is more efficient. It's a similar centralized versus distributed energy debate happening with other forms of power production. And it's the same argument made by Bloom Energy as the justification for that company's widely used solid-oxide fuel cell technology. (Bloom has sold 150 megawatts of its distributed generation units, equivalent to 1 gigawatt of solar, according to the company.)

NanoConversion's device, called the C-TEC, would live in the homeowner's boiler or water heater and produce some of the home's electricity as well as its hot water. There is the potential for dramatic reductions in waste and emissions, according to the startup.

A number of technologies have been tried in pursuit of viable residential CHP -- whether it be fuel cells from troubled firm ClearEdge or now-defunct Ceramic Fuel Cells, Stirling engines from European firms and Dean Kamen, or internal combustion engines. The technologies must economically scale down to residential scale (~1 kilowatt), and that's not always easy.

Weird science

Drive by any office park in Silicon Valley and it's as likely as not that there are wild-eyed entrepreneurs doing dangerous things with weird materials in what is essentially a garage. NanoConversion has 12 engineers, many from SDL and JDSU, and bootstrapped its initial development from founders and friends before winning funding from Frank Marshall, a former VP of engineering at Cisco. As an investor at Big Basin Partners, Marshall was also an early funder of Covad and NetScreen.

The technology employed by this startup is the alkali-metal thermal-to-electric converter (AMTEC), invented by Ford in the 1960s. (NanoConversion actually purchased the remnants of the Ford technology and is using some of that vintage equipment today.)

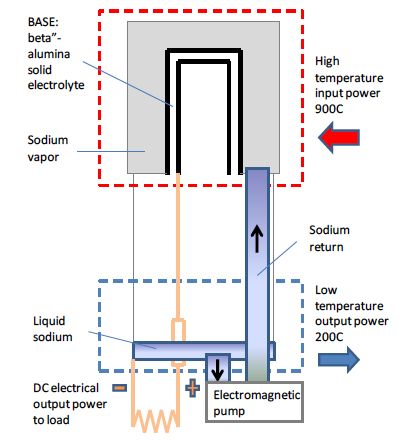

The device takes 850°C heat as an input and produces direct current electrical power and thermal heating power at 200°C, at potentially high efficiencies of up to 30 percent, according to Staskus, and when using the heat, over 90 percent. Because it's a closed system, the company claims that it is not subject to the fouling and reliability issues that can afflict fuel cells when contaminants in natural gas compromise the fuel-cell stack and "coke the anode." Because it has no moving parts, it was targeted for 15-year deep space missions with plutonium as the heat source.

The device makes use of a thermodynamic cycle of expanding and condensing sodium; the work generated by the expansion of sodium vapor is converted into electric power. Staskus likened it to a fuel cell where the fuel is burned outside of the unit, calling it "a fuel cell that doesn't die."

This is how the company breaks down the device's operation:

- Input heat vaporizes sodium

- Ion transport through BASE creates DC current

- The heat sink condenses sodium and delivers thermal power

- The electromagnetic pump returns sodium to the evaporator

BASE is the solid electrolyte material sodium beta-alumina. My tour of the NanoConversion garage included a primer on how the startup compacts alumina powder into a little ring which is then sintered using a Rube Goldberg microwave oven hack by the resourceful company. (High-tech startups have variously attempted to burn, smother or electrocute me in these types of demos, so I try to keep my distance.) The same beta-alumina material is also used in sodium-sulfur batteries.

We've covered the funding and development of semiconductor-based thermoelectric devices from companies such as Marlow and startups GMZ, Alphabet Energy, Phononic, and MTPV. These technologies have tended to have lower efficiencies than the AMTEC.

NanoConversion has a demonstration unit in the garage. Made of six cells, the device produces 3 watts at 2.5 volts and 1.2 amps, according to the company. The company also claims the device will last up to 15 years. As with other electrochemical devices, the small cell will be able scale akin to the way Tesla builds its battery packs with small 18650 form-factor lithium-ion batteries, in Staskus' view.

Applications for the novel thermoelectric device

A successful distributed power solution will have the characteristics of a boiler or water heater, according to the CEO. He said that residential CHP with a reasonable payback time (less than five years) opens up a multi-billion-dollar market for the startup that would produce customer-specific cogeneration subsystems for boiler manufacturers such as Rheem, Bosch, GE, and Rinnai. Staskus claims that 13 million boilers will be purchased each year for new builds and as replacements in the EU, U.S. and Japan.

But before the company gets to that mass market, it's going to need to prove out and scale its technology and manufacturing. Its initial target markets are off-grid -- a bit more niche-y than residential power.

- When power is needed for an off-grid system or device in an extremely remote location that can't be regularly serviced, a solution provided today by firms like Global Thermoelectric is to burn propane (in a big tank) and heat a relatively low-efficiency semiconductor thermopile. This configuration is used to power telemetry at oil well sites and communications for rural communities, as well as a surprising range of other applications.

- The technology could also be used to provide auxiliary power for diesel trucks at idle.

- Another remote application is cathodic protection of pipelines. Any natural gas pipeline in alkaline soil will plate itself away in about a year, according to Staskus. The pipeline operators keep some current flowing through the metal, and that inhibits plating in the pipeline.

- Flare gas energy recovery is another potential application.

- Government hijinks could also be powered by the device; Staskus spoke of operations where those in power feel the need to bury something in the desert that needs "several watts for five years."

- The military is always looking for better remote power.

Staskus also suggests that residential solar with micro-CHP and battery storage will be the best residential energy solution when net metering eventually subsides, because on-site baseload power reduces the solar array and battery size and cost to reasonable levels.

The startup is looking to raise a $10 million round B to move the company from technology demonstration to product development.