Meetings with greentech start-ups are usually cordial affairs.

Unlike my meeting with Zajac Motors, in which the management team alternately tried to burn and asphyxiate me.

Zajac Motors had a point to prove. The firm is developing a wildly efficient and innovative twist on the diesel engine and is using a new insulating material as part of the design. Mr. John Zajac, founder and CTO of the company, placed a small square of this ceramic material on my palm and proceeded to direct the flame of a 2,000-degrees-Celsius blow torch on the material. I suffered mild anxiety but no immolation. It's this material that allows the company's engine to be a "hot wall reactor with ten times the duration for a complete and clean combustion," according to Zajac.

Later on, during a tour of the plant, Zajac's management team locked me in a small room while their modified internal combustion engine (ICE) ran at full speed. The engine is so efficient at burning fuel that its emissions are minimal and one can't even detect the odor of exhaust. Luckily, I survived another segment of the interview.

Here's what I learned from my near-death experience:

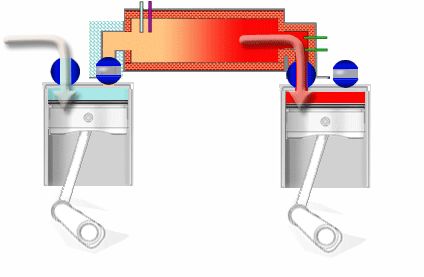

With a longer "residence time" and a constant temperature of 1425 degrees C, their split-cycle engine can make carbon fuels "virtually clean." The engine certainly emits CO2, although only half as much as conventional diesels. The emissions of CO, NOx, and particulates is negligible due to the high heat in the "green combustion" chamber.

Instead of intake, combustion and exhaust taking place in one location, Zajac performs these separate functions in separate places. The distinct combustion chamber leads to better efficiency and much better emissions performance. The secret to making the engine work is in the design of the valves -- the patented Zajec variable timing valves require much less power to operate than conventional valves, which can use up to 10 percent of a conventional engine's horsepower.

The design of this engine allows Zajac to jettison timing chains, mufflers, plugs and catalytic converters. The new design actually adds eight new components but removes 29 other parts.

The constant temperature of 1425 degrees C and constant pressure of 600 psi make this an engine which is "self-cleaning" and one in which the valves "can't get dirty."

According to the firm, the new technology also promises a dramatic increase in fuel efficiency (up to 50 percent more than conventional gas engines) and the ability to change fuels on the fly, without any alterations to the engine or its power rating. Modifications to the engine are entirely above the cylinder head.

The U.S. diesel engine market is worth $12.7 billion, according to the Fredonia Group. The first market target for the early stage firm is the substantial off-road engine sector -- construction, oil, mining and marine. The firm envisions a mix of revenue from sales of valves and chambers, as well as a licensing/royalty stream. There is the potential to move into on-road vehicles after that. The worldwide internal combustion engine market represents a $400 billion opportunity.

The Zajac Motors team members are hands-on entrepreneurs with varied backgrounds, albeit with a mildly homicidal mien. They've raised $3.5 million from angel investors and have a working prototype with which they are currently threatening journalists. They are in the process of raising their next round.

The team claims that their invention can "establish U.S. leadership in clean ICE technology." Other start-ups working on internal combustion engines are Achates Power and Transonic Combustion.

In the words of the Zajac team, "We are not making engines, we are making them better."