Two state-of-the-art photovoltaic module testing labs in the San Francisco Bay area show the industry's progress in validating solar panel performance, durability, and reliability.

PV Evolution Labs

The renovated warehouse near the Berkeley waterfront that houses PV Evolution Labs (PVEL) is often cluttered with some 50 palettes of modules. The modules are labeled with some of the biggest names in solar (which must, for proprietary reasons, go unnamed here).

"The diligence needs of the solar industry are evolving quickly,” PVEL CEO Jenya Meydbray said. His lab’s activity level reflects the industry’s increasing effort to document module performance in response to the demands of risk-averse finance and insurance providers.

On the day that GTM paid a visit, testing equipment was set out around the 11,000-square-foot, two-story space in a way that at first glance seemed haphazard. But after an hour-long tour led by PVEL development engineer John Watts, it was clear the space and the operation were highly organized.

The flash test chamber was nearest the area where incoming palettes were stacked. Heavy black curtains created a dark box in which a panel’s response to ten-millisecond light flashes registered IV curves on a nearby computer monitor. The curves confirm manufacturers’ submitted specifications and provide baseline data for before-and-after-testing calculations.

Watts said the lab typically flash-tests 50 modules per day.

Next was a table under a strong overhead light where visual inspection of modules is conducted to spot anomalies such as damaged glass, solder joint flaws or visible cell cracks. A monocular magnifying glass of the type that jewelers often use to inspect gemstones was close at hand. Visual inspection of normal modules takes three minutes to five minutes, Watts said. Nearby, there was a large, shallow, water-filled tub and a generator for the wet hipot test. Modules are immersed and a current is applied to check for amp leakage.

Around the corner was the electroluminescence testing room. In the dark, a camera images the module as current is pushed through. It radiates in the near infrared spectrum. “The image reveals irregularities and variations,” Watts explained. “Damaged cells can easily be spotted because they are less bright.”

For the durability and reliability tests that make up what the industry has begun to call "bankability evaluation," each of four large chambers induce a different type of environmental stress: damp heat, humidity freeze, thermal cycling, and UV exposure.

On an average day, there are about 75 modules in the chambers. Test procedures range from ten days to 1.5 months or more.

Across the warehouse floor from the environmental chambers was the dynamic mechanical load tester. It uses an air bladder and piston pressure to induce intermittent force on the module and frame. Near it was a solar simulator with an array of bulbs that match the sun’s light spectrum.

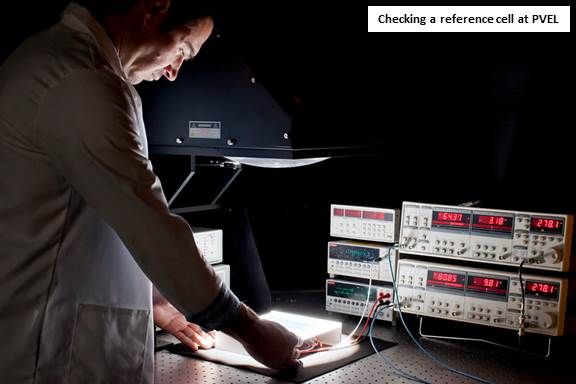

The last stop was the small, dark, electronics-filled room where PVEL builds solar reference cells. They are essentially portable irradiance detectors that allow developers to test their projects' actual performance against theoretical ideal performance.

Yingli America’s Photovoltaic Testing Lab

The newer, two-story Yingli Americas Photovoltaic Testing Lab (PVTL) in south San Francisco seemed larger and airier than the PVEL space. Much of its 12,000-square-foot floor was open, probably because it almost exclusively tests modules manufactured by Yingli Green Energy (YGE), its parent company.

The PVTL cuts costs for Yingli, explained Operations VP Brian Grenko. “Third-party testing is expensive. Our PAN files are based on data produced here which are then validated by a third-party lab like PVEL.”

PVTL had much of the same testing equipment that PVEL did for flash, mechanical loading, and environmental stress tests.

But PVEL sends modules offsite to test outdoor performance, while the unobstructed south-facing PVTL roof is covered with a 23-string, 84-kilowatt solar array on ballasted PanelClaw racks. They are primarily Yingli modules, but other leading manufacturers’ panels are also interspersed throughout the array. On the south side of the building, there is also a 4-string, ground-mounted, fixed-tilt array of Yingli utility-scale modules. The arrays feed to the PG&E grid via 27 wall-mounted SMA inverters sited inside the warehouse.

Mounted on the same warehouse wall is a specially designed data acquisition system that processes 57,000 data points per minute, explained Yingli Americas Reliability Engineer Ryan Desharnais. It has dedicated DC, AC, and temperature measurement capabilities, allowing detailed comparative performance evaluation of various system architectures, including those with distributed electronics.

Because it allows deeper insight into the causes and outcomes of module degradation, that granular data proved to be fundamental to the design of Yingli’s performance guarantees, Grenko said.

Detailed data gathered on module power outputs with different clamp options led to over $1 million in installation cost savings, Grenko added. An EPC for a large project now under construction with Yingli modules in Southern California was able to make the most cost-effective clamp choice.

The data from the PVTL roof is also essential to Yingli engineers’ efforts to accurately correlate accelerated lab testing with real-world performance. That exact relationship remains a mystery, Desharnais acknowledged, and yet is fundamental to the increased module bankability Yingli is working toward.